Manufacturing Execution System / MES – Smart Factory Glossar

A Manufacturing Execution System (MES) is used to plan, control, monitor, and optimize production. The MES software collects a multitude of data in real time, bundles the information, and prepares it for analysis to provide a more transparent and responsive manufacturing process. An MES empowers employees to respond in a targeted manner to short-term and unplanned events in their daily production routine. They can then initiate appropriate countermeasures without loss of time.

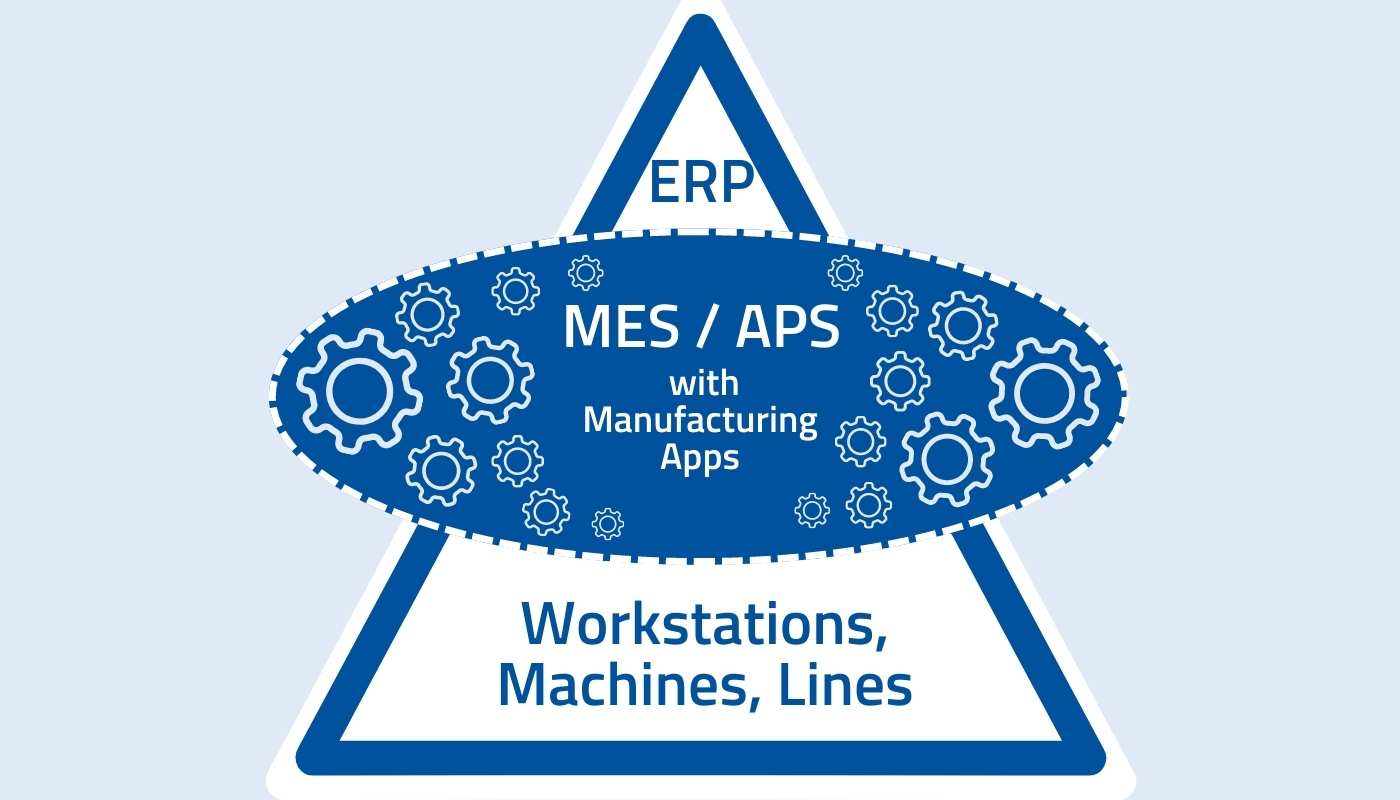

An MES is located in the automation pyramid between the control level in the shop floor and the enterprise level of the Enterprise Resource Planning (ERP) system and connects these two levels.

Tasks of an MES system

The Association of German Engineers (VDI) sets out the exact functional scope of manufacturing management systems in its VDI Guideline 5600. A total of ten MES tasks are stipulated in this document and listed below:

- Order management

- Detailed scheduling and control

- Resource management

- Material management

- HR management

- Data collection

- Performance analysis

- Quality management

- Information management

- Energy management

Flexibility of MES systems

Not every MES covers all of the above fields. There are providers of manufacturing execution systems that outsource detailed production planning to an advanced planning and scheduling system (APS). Other MES providers focus on HR functions or data collection, and quality management. This focus on specific applications illustrates the current trend: monolithic and consequently rigid systems will be displaced by modular software solutions in the long run. After all, since the MES functional scope was first documented by the VDI, the manufacturing world has not stood still and evolved into the future vision of Industry 4.0.

Thanks to sophisticated information and communications technology, processes in industry are becoming more and more intertwined, and machines and systems are closely networked. As a result, new requirements are being placed on the flexibility of manufacturing execution systems, which is outlined on sheet 7 of the VDI Guideline with case studies from the working environment. The latest guideline was developed with the participation of MPDV experts and states that "the conventional MES as a monolithic software application will break down into individual independent applications/apps and will also use and integrate external services" [VDI 5600 Sheet 7 / p. 12]. It further explains that the basic tasks associated with manufacturing management will remain unchanged in the future but will expand.

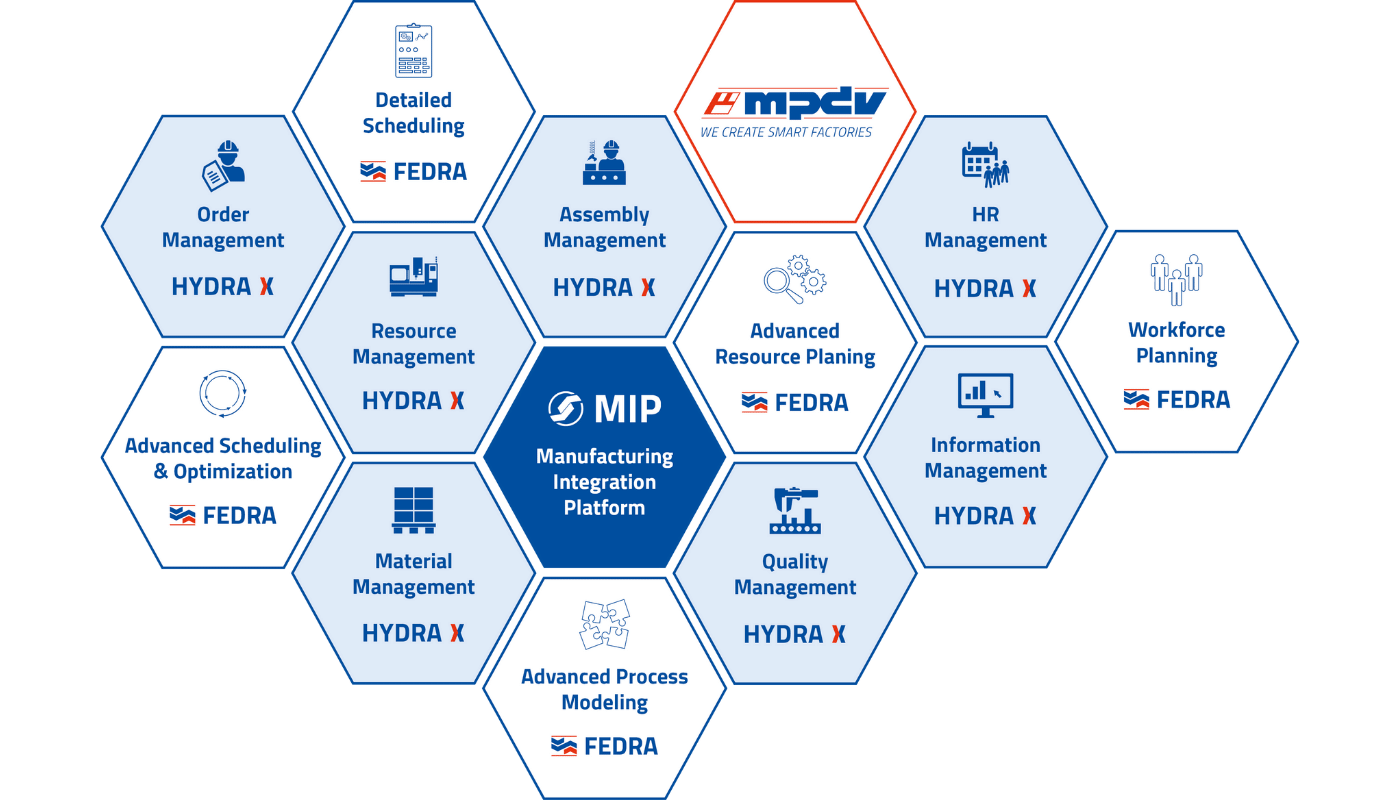

Interaction with the MIP integration platform

As early as 2018, MPDV launched the Manufacturing Integration Platform (MIP) to comply with new requirements. Based on the MIP integration platform, a variety of MES and APS applications can be operated individually or in interaction with each other. Since all manufacturing apps use the same uniform database, they are compatible with one another. MPDV contributes a multitude of manufacturing Apps (mApps) to the MIP with MES HYDRA and APS FEDRA. All mApps are bundled thematically, with categories reflecting MES tasks according to the VDI. MPDV's manufacturing apps are supplemented by applications from other providers and partners - everyone brings what they do best to the MIP ecosystem.

Functionality of a Manufacturing Execution System

An MES system aims to make manufacturing more efficient. As mentioned at the beginning, an MES handles planning and control tasks, manages production processes, and analyzes operations. Huge amounts of data are generated and processed to inform production staff and management about events in the shop floor at all times. This knowledge empowers managers and supervisors to take countermeasures early if they identify a problem. For example:

- ... if technical problems occur on a machine and machine values suddenly deviate from the norm.

- ... if raw material cannot be used due to quality issues.

- ... if staff is unavailable at short notice or lacks the necessary qualification to operate a machine.

- ... if a higher scrap rate delays the delivery date.

A comprehensive database makes a decisive contribution to reacting to such disruptions in the short term and identifying potential for optimization in the medium term. Beforehand, the relevant data on employees, machines, materials, and other resources relevant to production must be digitally mapped in the MES software. An MES relies on machine data and shop floor data collection and provides a complete and accurate picture of the manufacturing reality: the digital twin.

The ERP provides part of the data from the corporate management level and machines in the shop floor supply the remainder of information. The MES combines all this data at the production management level to achieve end-to-end transparency. The MES collects machine data via interfaces. Old machines are connected to the production IT quickly and cost-effectively with an IIoT connector. If the machine statuses cannot be called up directly, it may make sense to enter the data manually.

Advantages of an MES for companies

The core functions of a Manufacturing Execution System are designed to create transparent, economical, and responsive processes that are continuously optimized as part of the Continuous Improvement Process (CIP). Below are specific examples of the advantages of a MES solution:

- Lead times can be reduced significantly.

- Production capacities are utilized to a greater degree.

- WIP and inventories are cut back.

- If used correctly, accurate delivery dates can be predicted.

- Setup times can be brought down considerably in the course of setup change optimization.

MES software at work

The videos illustrate the functions of MES HYDRA X and show the software at work.

MES HYDRA X at work at a customer.

FAQ: Frequently asked questions about Manufacturing Execution Systems

These three letters abbreviate the term Manufacturing Execution System in the manufacturing and industrial environment. Another commonly used name is Production Management System or Production Control System.

A Manufacturing Execution System (MES) is positioned at manufacturing control level and has an organizational focus. An MES collects manufacturing data in real time, processes, and visualizes the information. This makes an MES ideal for keeping an eye on production and making processes transparent and efficient. The aim is to avoid waste such as waiting times or scrap. Machine operators or people responsible for production can identify potential for optimization and derive improvements.

The Enterprise Resource Planning system (ERP) is superordinate to the MES system, located at corporate management level, and addresses business aspects. It supports all business processes of a company, which are customer orders, invoicing, and all matters relating to profitability of the company. The focus of the ERP is on providing end-to-end assistance for processes and ensuring the exchange of information.

The Industrial Internet of Things (IIoT) enhances current systems and gives manufacturing IT a technical view of things like the use of machines and equipment, including their performance. Manufacturing only truly becomes a Smart Factory when all systems work together in perfect synergy.

A spreadsheet program like Excel is one of the standard Microsoft Office tools and has an immense range of functions. These functions make it possible to show all conceivable planning options but is extremely error-prone due to its complexity. The reason for this is not so much the tool as the user: Since the person responsible for planning enters the data manually into the Excel file, copy-and-paste errors, typos, or problems with the stored formulas are inevitable. Besides that, entering data and planning manually is very time-consuming and in case of unforeseen events such as a machine breakdown or illness, the planner starts all over again. In an MES, planning conditions can be configured as best suited. MES planning runs automatically step by step observing the stored conditions.

Whether in HR management or in performance analysis, for which the calculation of KPIs is essential, an MES is far superior to an Excel sheet in other functional areas as well. A Manufacturing Execution System has standard applications to automatically calculate things like incentive wages or even the Overall Equipment Effectiveness (OEE). Users can retrieve the result in real time and apply it immediately to their further work.

MES HYDRA is a Manufacturing Execution System from the software provider MPDV Mikrolab GmbH. The current version HYDRA X was launched in spring 2021. The MES software is unique as it is platform-based and the range of functions goes far beyond the classic tasks as described in VDI Guideline 5600. For instance, there are supporting functions for controlling intralogistics processes or providing operator guidance in assembly processes. On top of that, HYDRA X is not a monolithic system as was previously the case, but is made up of many user-friendly applications, the manufacturing apps. These mApps interact on the Manufacturing Integration Platform and can be combined according to the user's requirements. It is also possible to use external manufacturing applications on the MIP.

The history of MES HYDRA dates back to 1986: At that time HYDRA conquered the market as the first standard software for manufacturing and HR management. Some 20 years later, MPDV delivered HYDRA 7, the first modular MES system. The next generation, HYDRA 8, made its way into the production halls in 2012. HYDRA 8 was the first Manufacturing Execution System from MPDV to be based on VDI Guideline 5600, thereby heralding a completely new generation of MES systems.

Would you like more information? We are happy to help.

Send us an e-mail. We will take care of your inquiry promptly.