Smart Factory Hive

The Future of Manufacturing IT

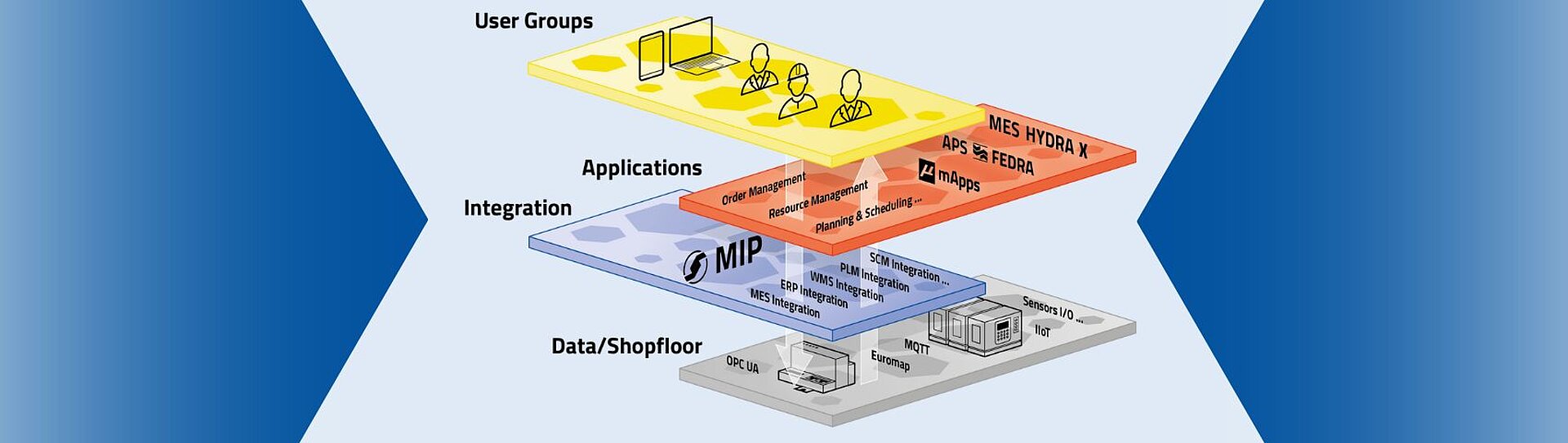

With the Smart Factory Hive, MPDV has developed a new and innovative approach for the Smart Factory. This concept goes beyond the automation pyramid. The pyramid approach has come to its limits these days since it is difficult to integrate new IT architectures into the classic pyramid structure. Furthermore, the layers of a pyramid can only communicate with the neighboring segments. What we need today is a network where all systems can directly communicate with each other, regardless of the layer they are in. However, this large number of communication interfaces significantly increases complexity. MPDV provides the means to reduce this complexity by introducing a central platform with all systems and equipment being connected to this platform via one standardized interface. To visualize this network, MPDV uses a multi-layer honeycomb structure, inspired by nature. The compact honeycomb structure reduces interfaces and transforms complex IT architectures into clear and flexible systems.

Smart Factory Hive as a window to the future

The Smart Factory Hive catapults manufacturing IT into a whole new era. The new perspective gives providers and users alike a fresh and future-oriented view of IT in the Smart Factory. It seems like we have opened a window to the future. The manufacturing IT of the future is no longer just a concept – it is starting here and now, opening up new possibilities for greater efficiency, better connectivity, and continued innovation.

Nathalie Kletti, Chief Executive Officer at MPDV

Smart Factory Hive: efficient communication between layers

The example of a punching machine can perfectly illustrate how the different layers interact in the Smart Factory Hive. The Smart Factory Hive visualizes how data makes its way from the shop floor to the user, providing a transparent view of the application hierarchy.

- Data flow: In the architecture of the Smart Factory Hive, the machine control (Data/Shop Floor) collects every single cycle of a punching machine via OPC UA.

- Integration: The DEC edge component (Integration) transmits the cycle signal via web service to the central Manufacturing Integration Platform.

- Visualization: The mApp Machine Monitoring (Applications) shows the counted cycles and the produced quantity on the shop floor client where the operator (User Groups) monitors the order progress.

- ERP integration: The order progress is forwarded to the ERP and CRM systems via integration modules. If delays occur, the customer is promptly informed.

- Energy monitoring: The machine's energy consumption is recorded and sent to the integration platform via DEC. The data is directly transmitted to the facility management system.

- Maintenance management: The mApp Maintenance & Service Management (Applications) checks the energy consumption. If excessive consumption is identified, the system automatically schedules a maintenance activity for the punch and notifies the maintenance staff (User Groups) on the smartwatch.

The four layers of the Smart Factory Hive

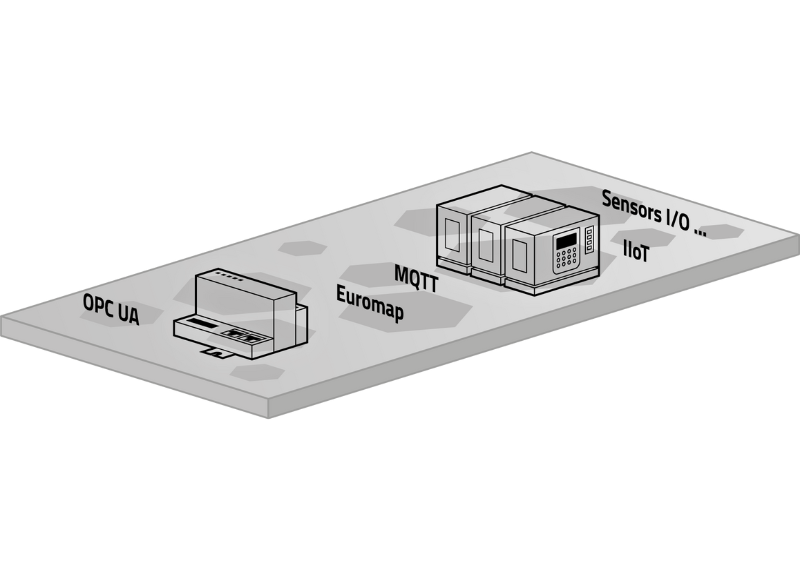

Data/Shop Floor

All data suppliers are located on the bottom layer. This layer contains machines, control systems (PLC), robots, and tools, as well as communication protocols such as OPC UA, MTconnect, or MQTT. Also automation and IIoT platforms communicate on this level.

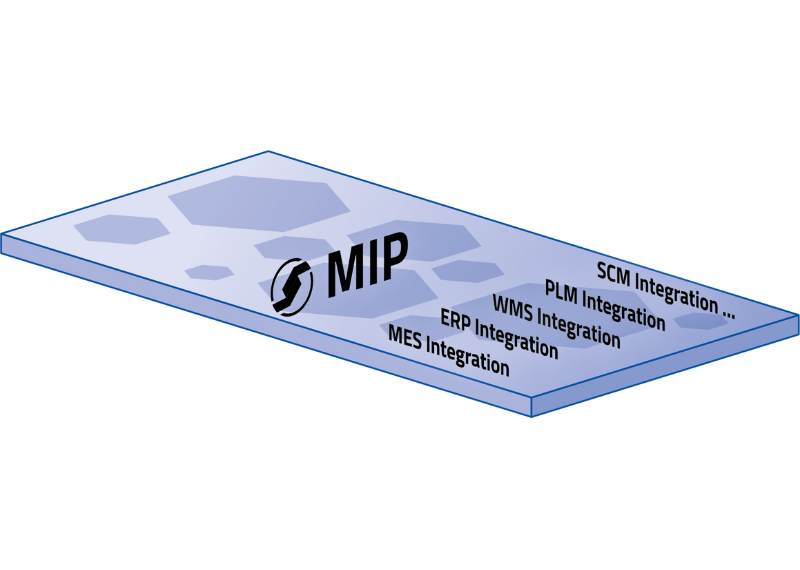

Integration

Wherever data is processed, distributed, or analyzed, an integration platform ensures that the required data is available. The integration platform connects the shop floor to the higher-level applications. The integration modules for ERP, PLM, SCM, (intra)logistics, or CRM systems are also assigned to this layer.

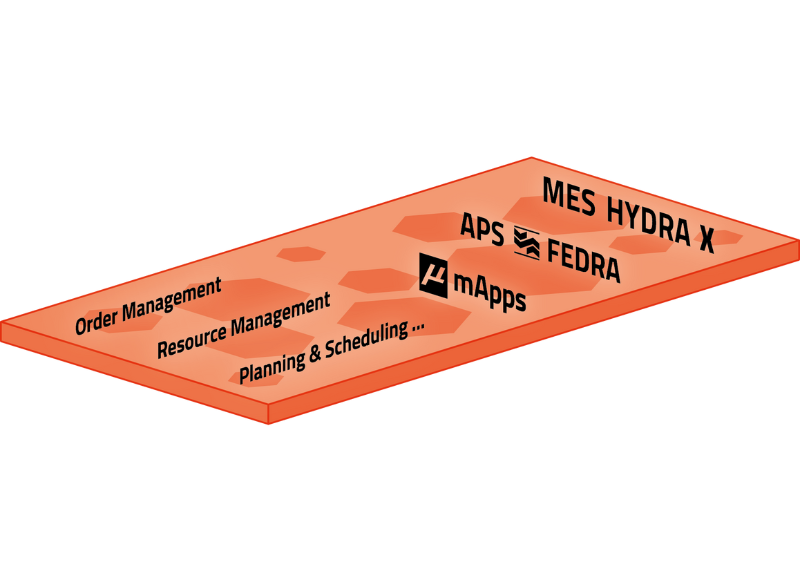

Applications

This layer includes all kinds of applications of manufacturing IT. These are classic MES tasks in accordance with VDI guideline 5600 and new fields of application such as Assembly Management or analyses with artificial intelligence.

User Groups

The user groups in a company are assigned to the top layer. Operators, supervisors, planners, or production managers are users. And also employees of the controlling, purchase, development, and process management departments as well as the executive board are located on this layer.

Smart Factory Hive for different target groups

The objective of the executive board (User Groups) is to generate revenue. For this to work, production is the most important factor in a manufacturing company. The management requires meaningful KPIs and reports, which are ideally displayed on a dashboard. Key data such as the Overall Equipment Effectiveness (OEE) or the current sick leave are exactly what they are interested in. For this purpose, executive managers use an application of a Manufacturing Execution System (Applications).

A production planner (User Groups) distributes orders to machines trying to optimally use the machinery. Planning also integrates tools, material, energy, and personnel, which creates a lot of data. It is also important to know whether an order has just been transferred from the ERP system or is already logged on to a machine. The planner needs access to a planning tool such as an Advanced Planning and Scheduling System (Applications) and up-to-date production data. If an integration platform such as the MIP (Integration) is used, the planning tool gets all required data from the shop floor and orders from the ERP and processes this data to ensure perfect planning.

The head of IT is responsible for the smooth interaction of all systems. An integration platform (Integration) is the perfect means for this to work as it provides standardized access and minimizes the number of interfaces. New devices are easily connected and applications can directly access data. If systems are changed, only the interfaces to the platform must be replaced. Interoperability is decisive for the IT manager whereas applications (Applications) and users (User Groups) are only considered for administration purposes.

Every move of an operator is mindfully executed to avoid scrap or danger. The operator requires precise data and instructions to produce efficiently and faultlessly. Applications of a Manufacturing Execution System (Applications) provide the operator (User Groups) with this kind of data. The status of machines and where specific measured values are recorded (Data/Shop Floor) are further important pieces of information for the operator.

The quality manager ensures that legal and customer requirements are fulfilled and guarantees product quality. They plan and perform inspections and analyze measurement data. The inspection itself can be carried out by an operator, but the quality manager decides on the users (User Group) performing the inspections and on the applications (Application) used in the process. Documenting the origin of measured values (Data/Shop Floor) is essential in this context. Finally, the quality manager requires information from the ERP or PLM, which are connected via an integration platform (Integration), for inspection planning.

One of the tasks of an industrial electrician is to connect machines digitally. Modern machines are connected via a standardized protocol such as OPC UA or MQTT. This task is often done by simply plugging in a network cable and configuring an IP address. With older machines, the electrician installs sensors (Data/Shop Floor) providing data to a data collection module in the shop floor or to a control cabinet. This device (Data/Shop Floor) is in turn connected to the integration platform as the data source (Integration).

White Paper Smart Factory Hive

In the Smart Factory Hive white paper, we present each individual layer in detail. You will also find striking examples of how the Smart Factory Hive meets the requirements of different target groups – from industrial electricians to production planners and executive board.

Would you like more information? We are happy to help.

Send us an e-mail. We will take care of your inquiry promptly.