Smart Factory Elements – Smart Factory Glossary

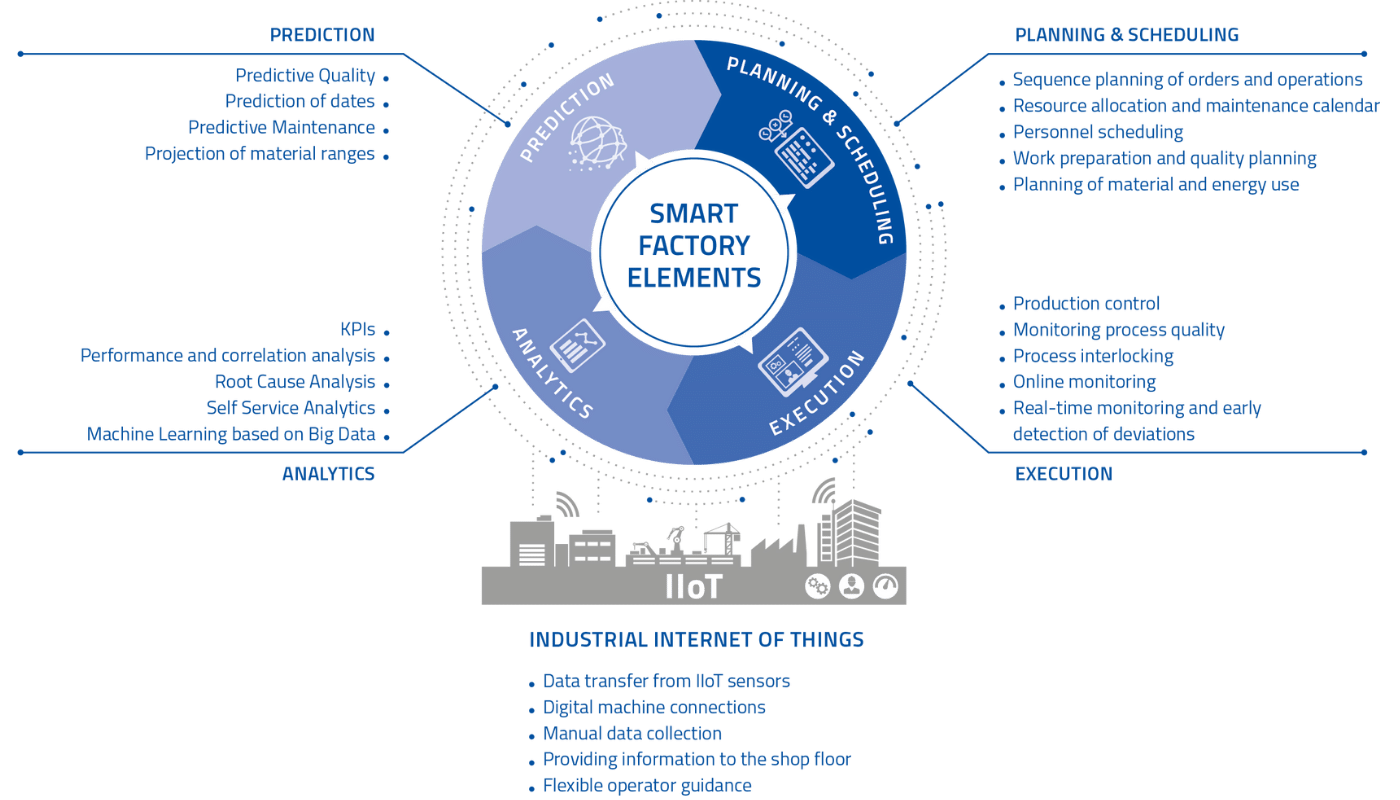

The "Smart Factory Elements" model offers an innovative solution for the complex requirements in manufacturing IT. The model's primary finding is that all elements together form a closed loop. This loop of the Smart Factory integrates all processes and data streams in manufacturing — from planning to execution.

The Smart Factory's loop includes the following elements:

- Planning & Scheduling: Production is planned based on specifications from different data sources. Planning includes orders and operations, as well as resources, employees, quality assurance, maintenance activities, and the use of material and energy.

- Execution: Different activities are performed as planned and manufacturing processes are executed according to schedule. It is very important that specifications are integrated efficiently and correctly. This element therefore covers not only production control, but also monitoring of process quality, early detection of deviations, and online monitoring.

- Analytics: Data collected in the manufacturing process is analyzed in the follow-up and used to make predictions. Evaluations and reports, long-time analyses, and machine learning on the basis of big data are only some examples of analytics functions. Applications in this area use artificial intelligence (AI) to make the best use of the data available. The Manufacturing Execution System (MES) HYDRA X by MPDV uses AI to analyze to what extent capacities are being utilized per shift, for example.

- Prediction: Data analysis is the basis for predictions. Closing the loop, the findings flow back into planning. Typical applications are predictive quality, the precise prediction of delivery dates, or calculation of material ranges. Applications of this area can also promote the economical use of resources.

Industrial Internet of Things (IIoT): The IIoT supports the loop by collecting and providing the data required for workflows. It connects the operator in the shop floor to the digital image of the Smart Factory. For this to work, data needs to be transferred from the IIot sensors or recorded manually, machines must be connected digitally, and information provided in the shop floor. The Manufacturing Integration Platform (MIP) from MPDV serves as a universal data hub for the IIoT.

Some of the tasks can be met with market-proven software such as the Manufacturing Execution System (MES) HYDRA X or the Advanced Planning and Scheduling System (APS) FEDRA. For other tasks, new products are developed step by step.

Sources

- MPDV Mikrolab GmbH: Smart Factory Elements – A model for the innovative production IT [Whitepaper], 2021, whitepaper.mpdv.com

Would you like more information? We are happy to help.

Send us an e-mail. We will take care of your inquiry promptly.