Operator Inspection – Smart Factory Glossary

The operator inspection or operator check is a concept to assure quality in manufacturing companies. It is characterized in that employees who are responsible for manufacturing a product check the quality of their work themselves.

A typical task of the operator inspection is to check intermediate and end products against predefined quality standards and specifications. Employees inspect products, take measurements, and perform checks to ensure that their work meets all specifications. If a product deviates from the standard, countermeasures can be initiated promptly, or corrections made. An operator inspection may also involve a preventive check of the working environment. The results of checks and inspections can then be stored digitally in a Manufacturing Execution System (MES).

Fields of application include numerous areas of manufacturing and assembly where efficiency plays a major role. However, operator inspection is also firmly established in the process industry, where high quality standards have to be met.

Benefits of operator inspection

- Fast reaction times: The operator inspection helps to detect and eliminate defects at an early stage. As a result, companies can reduce times and avoid costs if they have to scrap or rework products.

- Greater efficiency: As product quality is checked directly at the point of origin, problems are identified and rectified immediately. This means that production costs can be cut, and efficiency increased in manufacturing.

- Greater job satisfaction: Employees' quality awareness is sharpened, and their personal responsibility reinforced by actively involving them in quality control. This can lead to greater contentment in their work.

- More efficient processes: As part of lean management, operator inspection is an important component of the continuous improvement process.

Operator inspection in the software solutions by MPDV

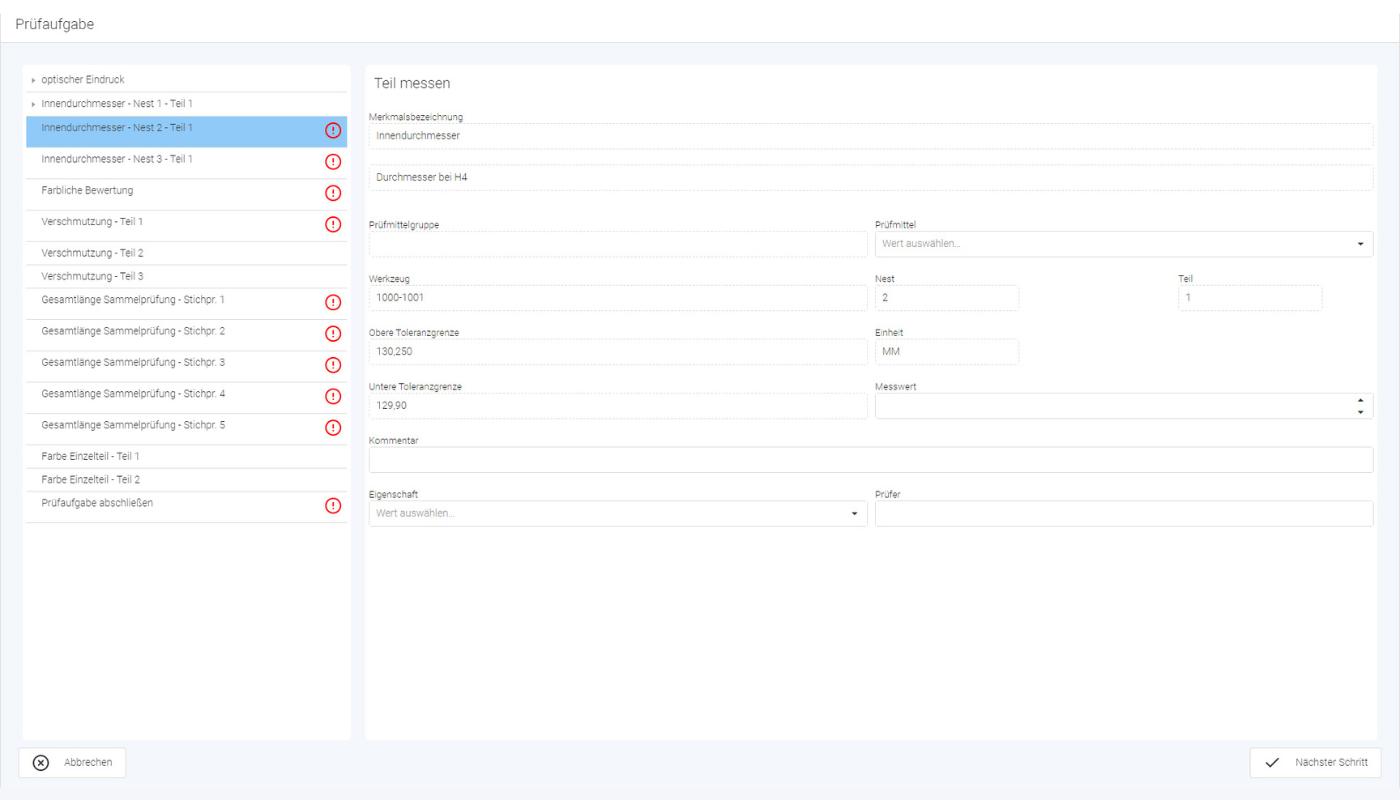

MPDV's Manufacturing Execution System (MES) HYDRA X provides applications for quality assurance in the category Quality Management. The Operator inspection is included in the mApp In-production Inspection enthalten. Use the quality management to digitalize in-production inspections.

MES HYDRA X automatically informs operators which inspection is pending and enables all data to be entered with user-friendly input screens. At the same time, the system documents the test equipment used. The operator can also transfer the measured values directly from the test equipment to avoid typing errors. As soon as the inspection task has been completed, the operator can decide whether to use the inspected product. If products are found to be faulty, the MES immediately informs persons defined in advance in the system.

Companies can save a lot of paper in their production as all inspection results are recorded and archived in the MES software. The mApp In-Production Inspection has therefore been awarded the "Promoting Sustainability" label.

Requirements for reliable operator inspection

It is vital that employees are trained and take on responsibility to implement a reliable and successful operator inspection. They should recognize the benefits of an operator inspection to meet personal work requirements, understand inspection instructions, and know how to deal with failed parts.

Would you like more information? We are happy to help.

Send us an e-mail. We will take care of your inquiry promptly.